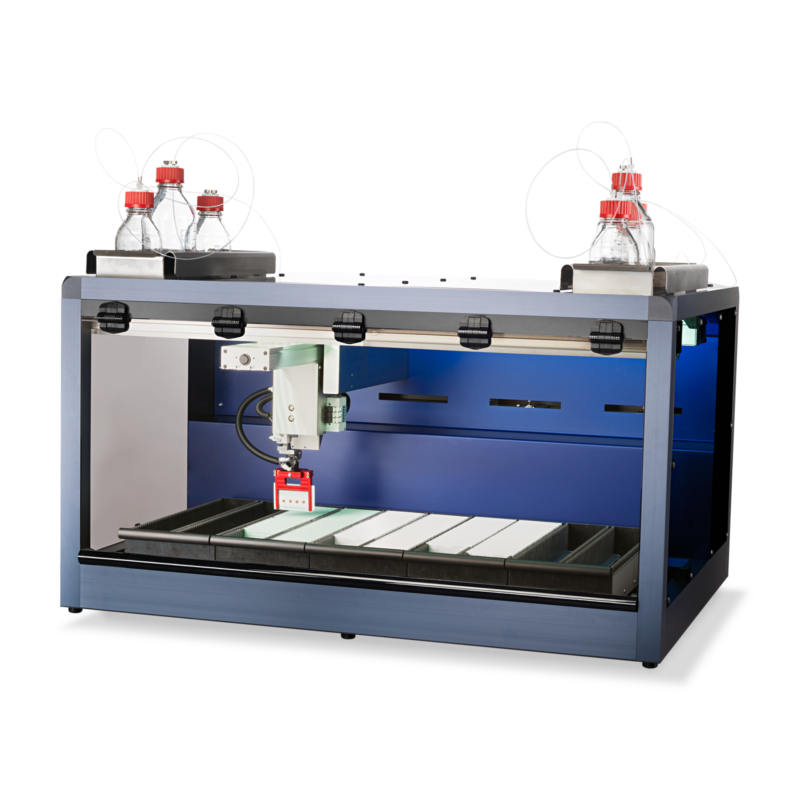

The fully automated DBS-MS 500 HCT

The fully automated DBS-MS 500 HCT from CAMAG contains state-of-the-art technology to extract target substances out of a DBS (Dried Blood Spot).

The DBS is directly eluted in the extraction chamber and the analytes are guided online to the analytical system of choice or the extract is collected into a vial or 96 well plate.

Sample processing is automated, including the application of an internal standard through a high-precision sprayer, detecting the sample’s hematocrit through an optical module, and a barcode assignment from the DBS card. In addition to the analytical results, a picture of each DBS card before and after extraction and the run parameters are reported to maintain full traceability and the highest quality.

-

High-throughput analysis of up to 500 DBS cards per run

-

Integrated optical card recognition and barcode reading module

-

Non-destructive hematocrit detection through an optical module

-

Automated internal standard application module

-

Unique extraction module with wash station to eliminate carry-over

-

Online coupling to the analytical system (MS or LC-MS)

-

Full control through Chronos software

Workflow

Optical card recognition

Hematocrit detection module

Internal standard application

Extraction module

Wash station

Master control software Chronos

Chronos

Optimization for high throughput

Robustness and repeatability

Safety

Real-time monitoring of analytes

The sample schedule is visualized in a chart which can be monitored in real-time (see image slider below).

- A) Transport the DBS card

- B) Optical card recognition

- C) Application of internal standard

- D) Extraction

- E) Rinsing the extraction unit

- F) Estimated LC-MS cycle time

Technical specifications

-

Height660 mm

-

Width1260 mm

-

Depth800 mm

-

Mains voltage115 / 230 V AC

-

Frequency50 / 60 Hz

-

Power consumptionMax. 130 W

-

Main fuse2 AT

-

Nitrogen connection5.5 – 8 bar

-

Ingress protection (IP)IP20

-

In-output connections

2 x RJ45

Power supply

Gas supply

Service connector

What you need to get started

Ordering Information

-

050.0501

CAMAG® DBS-MS 500 HCT

- Fully automated DBS workstation for 500 DBS cards.

- Including wash station, optical card recognition unit, hematocrit scanner, and internal standard spraying module.

- Master slave control unit.

- Chronos software to control the extraction, analysis, and PAL sample collection.