CAMAG®

Derivatizer

In a nutshell

THE BENCHMARK FOR REPRODUCIBILITY

The Derivatizer revolutionizes automated reagent transfer in thin-layer chromatography, setting new standards for reproducibility with its innovative “micro droplet” spraying technology.

This patented innovation not only guarantees ease of use but also adapts to various reagent needs. It supports a wide range of common reagents and tackles different physicochemical properties, like viscosity, using four distinct color-coded nozzles. Furthermore, with six different spraying modes, the Derivatizer allows users to tailor the process to their specific requirements, enhancing both efficiency and flexibility in chromatographic workflows.

By providing a highly consistent and versatile solution, the Derivatizer optimizes the derivatization step, ensuring high-quality results across various applications. This advancement makes it an indispensable tool for labs focused on improving accuracy and throughput.

-

Unsurpassed homogeneous reagent distribution

-

Reproducible and user-independent results

-

Low reagent consumption (2-4 mL)

-

Hood for 20 x 10 cm and/or 20 x 20 cm plates

-

Intuitive handling and easy cleaning

-

Environmentally friendly and safe handling through a closed system

Operation of the Derivatizer

01

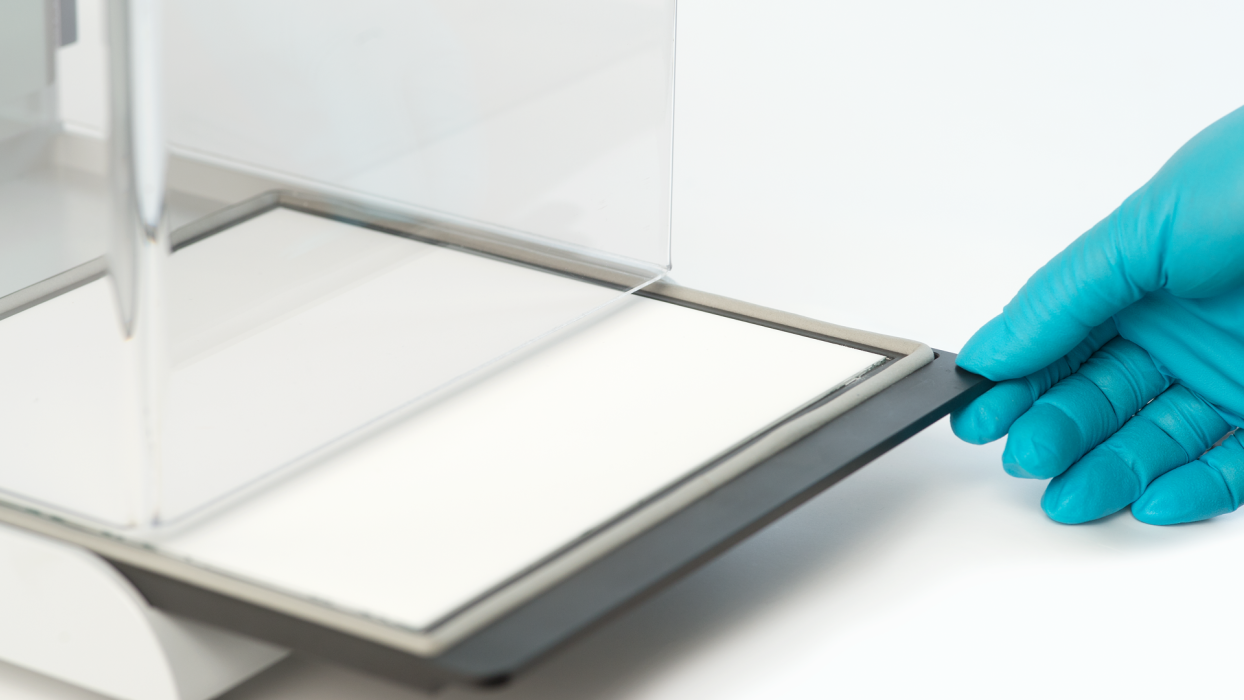

At the push of a button, the transparent hood effortlessly rises, allowing to access the plate tray for convenient placement of their HPTLC plate.

02

After the tray is inserted into its original operating position, the hood is lowered and completely sealed to prevent aerosols from leaking to the outside.

03

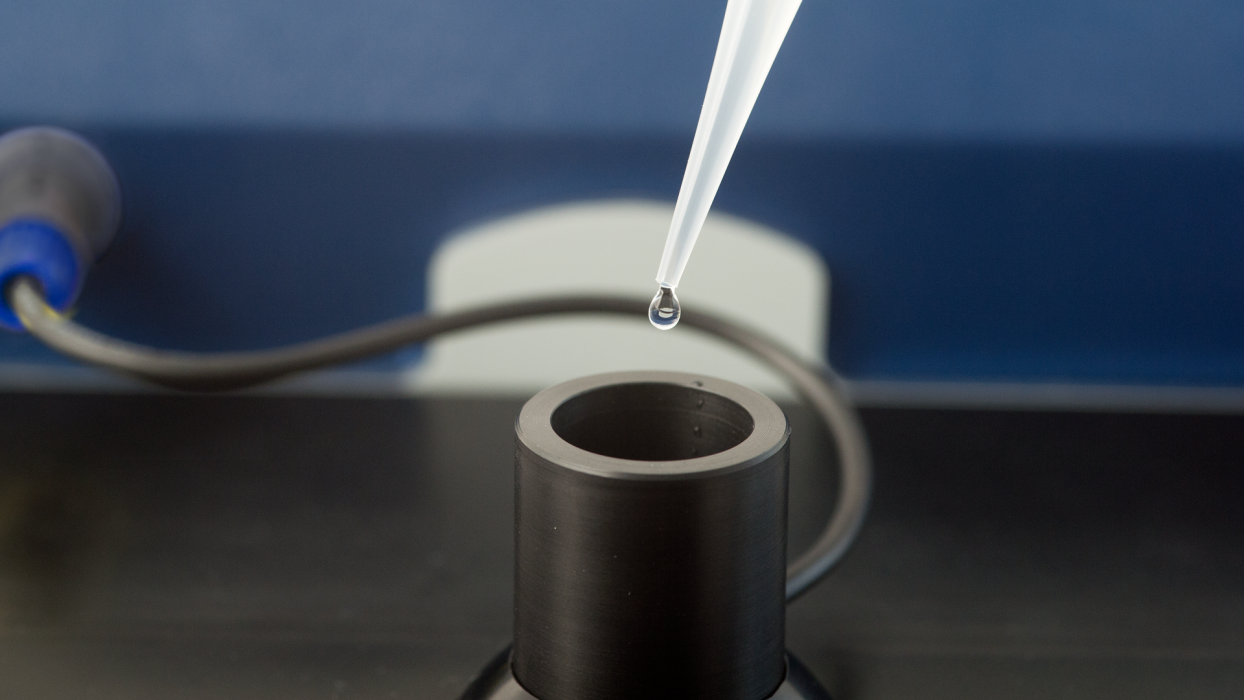

The user fills the required reagent volume into the appropriate nozzle, selects the optimum spraying level and starts the reagent transfer. To meet the divergent physicochemical properties of the reagents, e.g. viscosity, four different color-coded nozzles are available, and the user can select from six spraying levels changing the reagent throughput.

04

The nozzle generates an extremely fine reagent aerosol, which evenly distributes in the chamber and gradually settles down on the TLC/HPTLC plate.

05

Any residue remaining in the gas phase is automatically aspirated by the integrated pump and collected in the wash bottle behind the instrument.

06

After the reagent transfer has been completed, the hood lifts at the push of a button and the TLC/HPTLC plate can be removed for further processing.

Results

Derivatization means another step in the process of thin-layer chromatography, consequently causing an increase in variance. Even with a trained, expedient technician manually spraying a reagent, the coefficient of variation (CV) of the measured values rises up to 12 %.

Using the CAMAG Derivatizer, the CV increases by less than 5 %, thus providing very reproducible results, equal to those obtained with the Chromatogram Immersion Device, yet consuming considerably less reagent.

Natural product reagent sprayed with the Derivatizer

The following most common reagents have been tested and validated for use with the Derivatizer:

- Sulfuric acid reagent (10 % in methanol)

- Anisaldehyde reagent

- Natural product reagent

- Polyethylene glycol solution

- Iodine solution (0.5% in ethanol)

- Dragendorff reagent

- Fast blue salt B reagent

- Ehrlich’s reagent

- Phosphomolybdic acid reagent

- Ninhydrin reagent Copper (II) sulfate reagent

- Aniline-diphenylamine-phosphoric acid reagent

- Vanillin reagent

- Potassium hydroxide solution (5% in methanol)

- Aqueous solutions (enzymatic solutions, etc.)

For alternative spraying reagents and reagents that are problematic to spray, please download the recommendation list.

Technical specifications

-

Classification of installation and useClass I, installation category II, protection class IPX0, Pollution degree 1

-

Nitrogen or clean air pressure5 – 8 bar (70 – 110 psi)

-

Operating temperature15 – 30 °C

-

Recommended working temperature20 – 25 °C

-

HumidityMaximum relative humidity 80 % for temperatures up to 30 °C (Humidity and temperature conditions must not cause condensation!)

-

Plate typesHPTLC glass plates 20 x 10 cm, layer thickness 200 µm

What you need to get started

Ordering Information

-

022.6010

CAMAG® Derivatizer 20×10

complete set consisting of:

022.6030 CAMAG® Derivatizer Base Unit for the automated derivatizaton of TLC plates up to 20 x 20 cm using “micro droplet” spraying technology, 100–240 V

022.6055 Hood for 20 x 10 cm plates

022.6056 Tray for 20 x 10 cm plates

022.6061 Nozzle green

022.6062 Nozzle blue

022.6063 Nozzle yellow

022.6064 Nozzle red

022.6071 Tray Sealing for 20 x 10 cm plates (Pack of 5) -

022.6020

CAMAG® Derivatizer 20×20

complete set consisting of:

022.6030 CAMAG® Derivatizer Base Unit for the automated derivatizaton of TLC plates up to 20 x 20 cm using “micro droplet” spraying technology, 100–240 V

022.6050 Hood for 20 x 20 cm plates

022.6051 Tray for 20 x 20 cm plates

022.6061 Nozzle green

022.6062 Nozzle blue

022.6063 Nozzle yellow

022.6064 Nozzle red

022.6070 Tray Sealing for 20 x 20 cm plates (Pack of 5)

-

022.6080

Set of all four nozzles (green, blue, yellow, red)

-

022.6091

Set of three nozzles, green

-

022.6092

Set of three nozzles, blue

-

022.6093

Set of three nozzles, yellow

-

022.6094

Set of three nozzles, red

-

022.6085

Set of all four nozzles “Ultra” (green, blue, yellow, red)

-

022.6066

Nozzle “Ultra”, green

-

022.6067

Nozzle “Ultra”, blue

-

022.6068

Nozzle “Ultra”, yellow

-

022.6069

Nozzle “Ultra”, red

-

022.6096

Set of three nozzles “Ultra”, green

-

022.6097

Set of three nozzles “Ultra”, blue

-

022.6098

Set of three nozzles “Ultra”, yellow

-

022.6099

Set of three nozzles “Ultra”, red

-

022.6000

CAMAG® Derivatizer

complete set consisting of:

022.6030 CAMAG® Derivatizer Base Unit for the automated derivatizaton of TLC plates up to 20 x 20 cm using “micro droplet” spraying technology, 100–240 V

022.6050 Hood for 20 x 20 cm plates

022.6051 Tray for 20 x 20 cm plates

022.6055 Hood for 20 x 10 cm plates

022.6056 Tray for 20 x 10 cm plates

022.6061 Nozzle green

022.6062 Nozzle blue

022.6063 Nozzle yellow

022.6064 Nozzle red

022.6070 Tray Sealing for 20 x 20 cm plates (Pack of 5)

022.6071 Tray Sealing for 20 x 10 cm plates (Pack of 5)

Interested in the product?

Reach out to your local distributor and enjoy faster, improved results at reduced costs.