CAMAG® HPTLC PRO Module APPLICATION

HPTLC PRO

Module Application

CAMAG® HPTLC PRO

Module Application

In a nutshell

Precise and Consistent Sample Application for Reliable Results

[application-large]

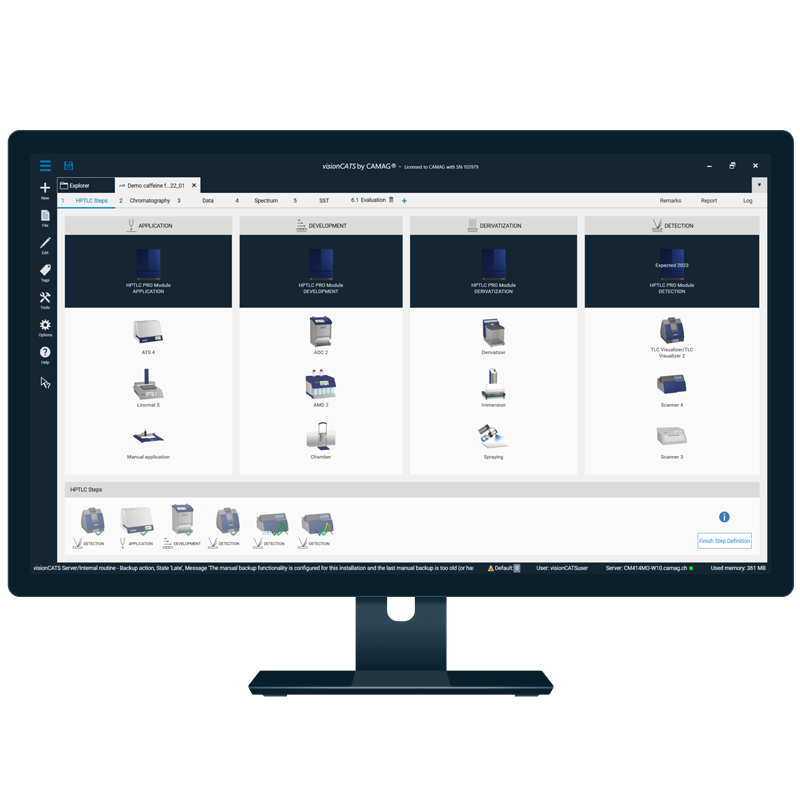

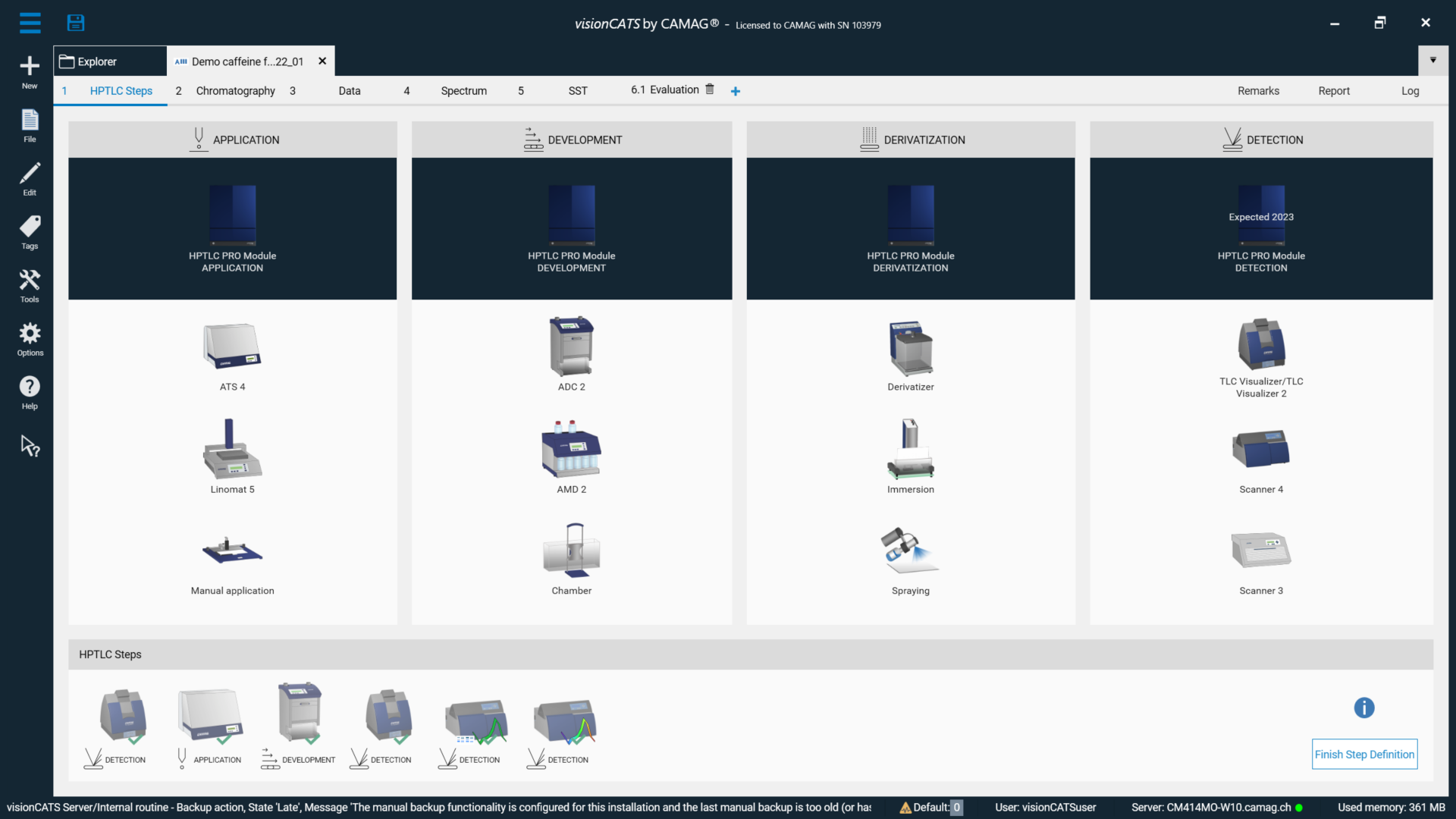

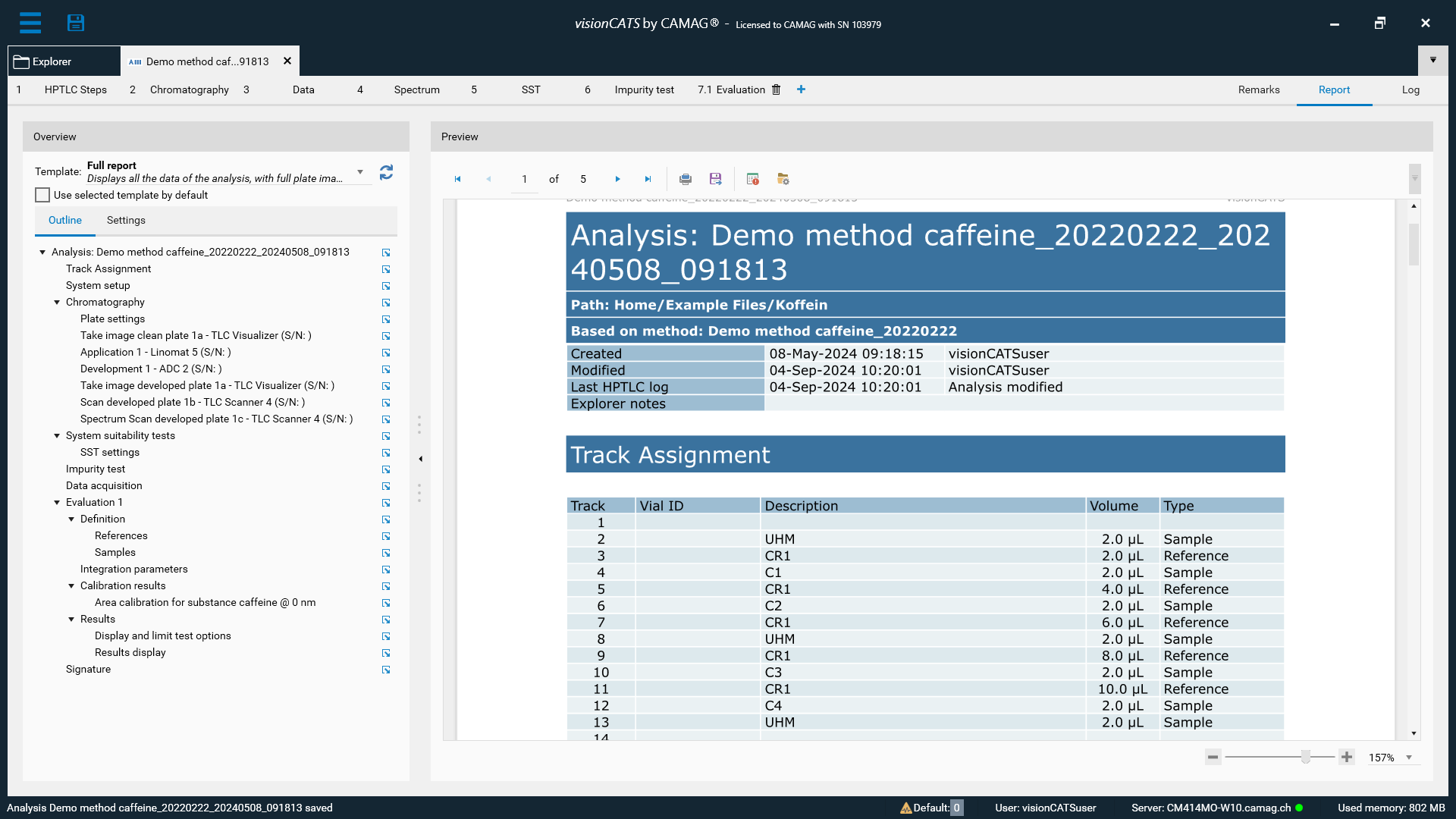

Controlled by visionCATS HPTLC Software, the autonomous application of up to 75 samples is supported (on up to five HPTLC plates).

-

Part of the fully automated HPTLC PRO SYSTEM

-

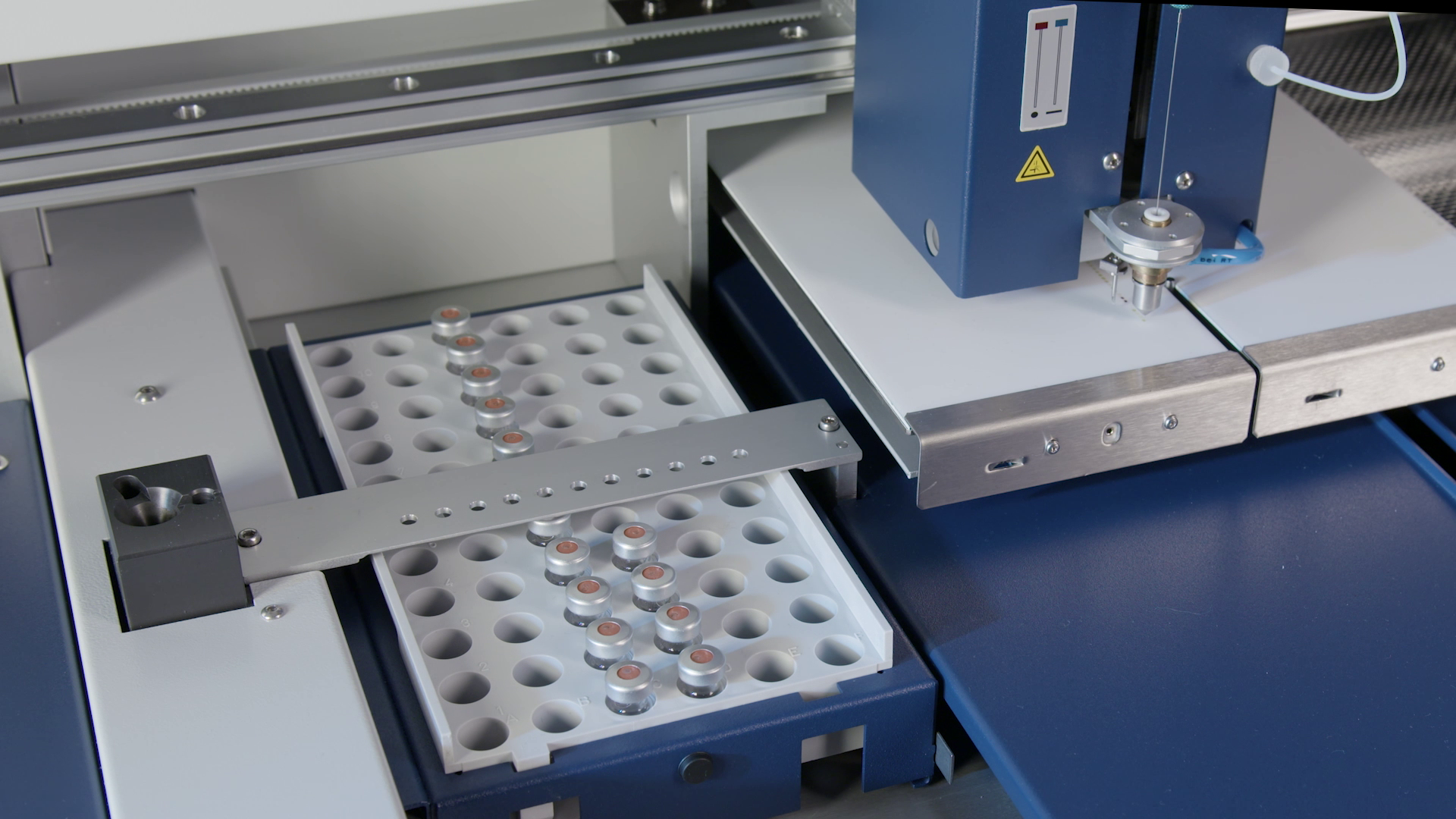

Autonomous application of up to 75 samples

-

Spray-on application of samples as bands

-

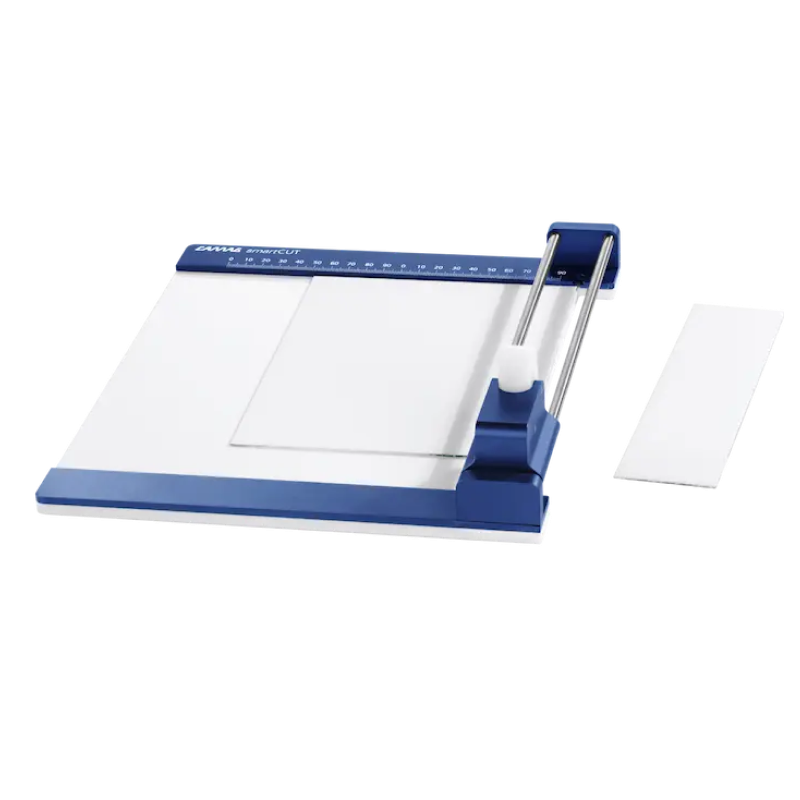

HPTLC glass plates (20 x 10 cm)

-

Software-controlled by visionCATS

Stand-alone operation

With HPTLC PRO, users have the choice to either operate a module as stand-alone or together with other modules in a SYSTEM MODE.

SYSTEM MODE

SMOOTH & PRECISE OPERATION

-

01

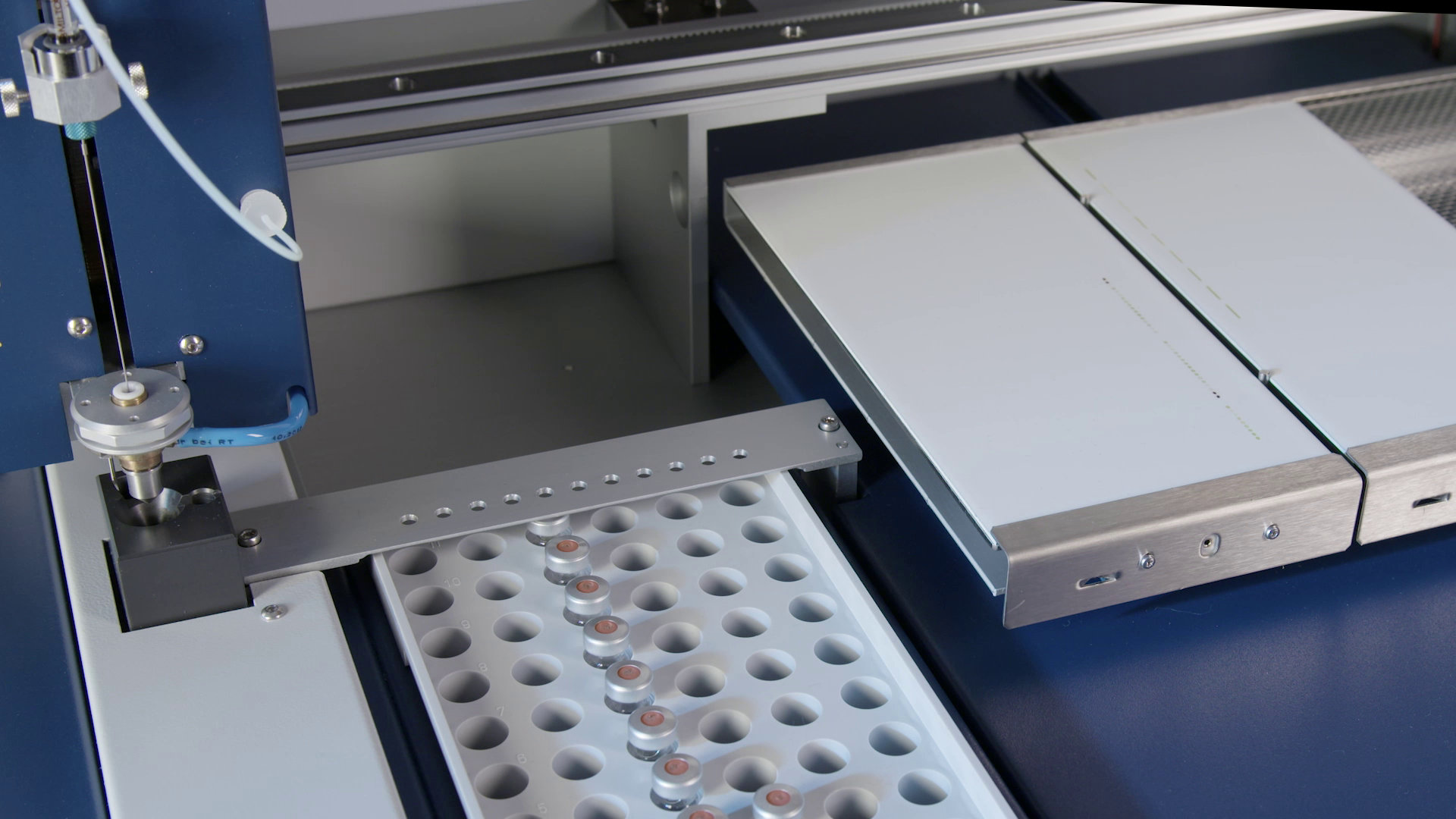

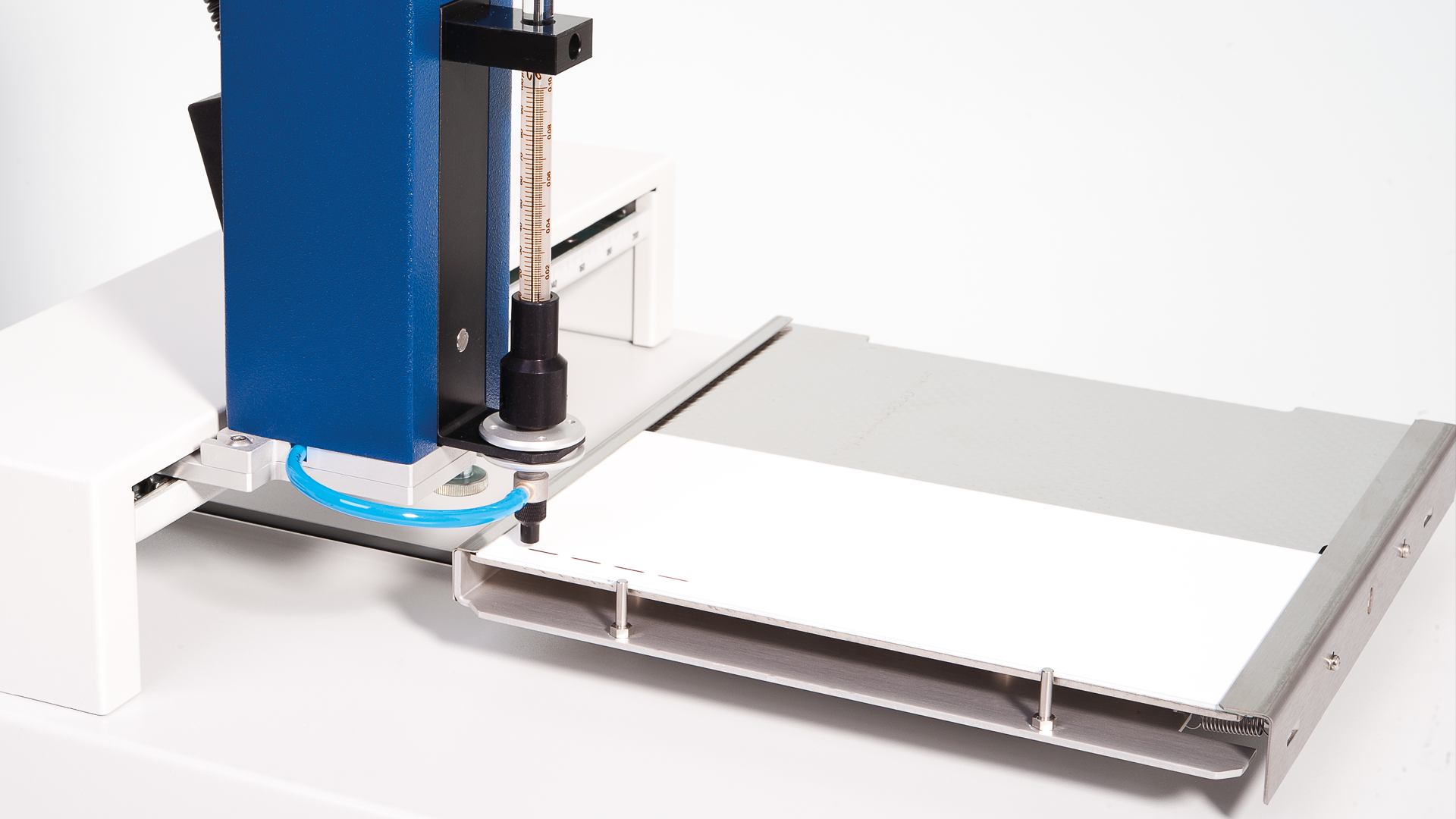

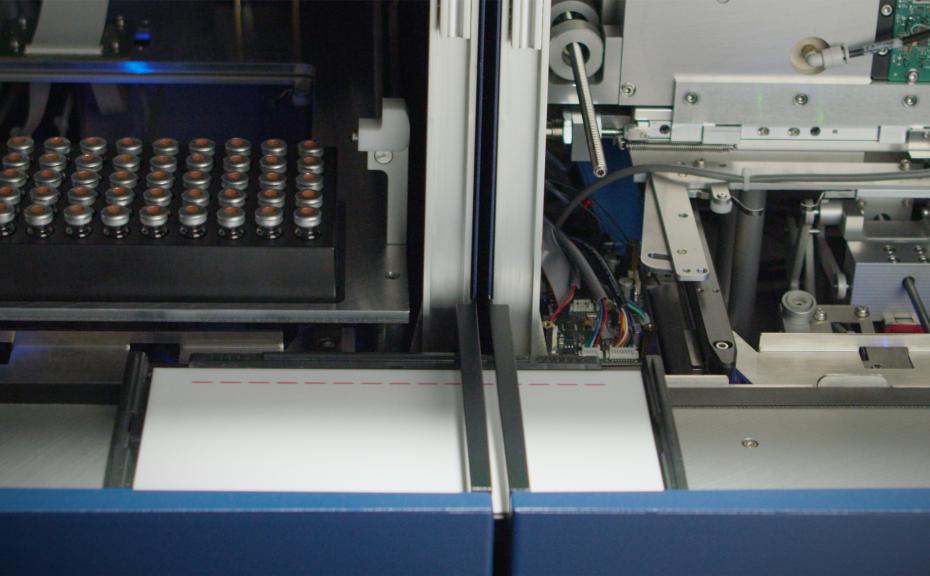

The HPTLC PRO Module APPLICATION can autonomously apply up to 75 samples across five different plates. For continuous operation, pair it with the Module PLATE STORAGE, which automatically supplies new plates.

-

02

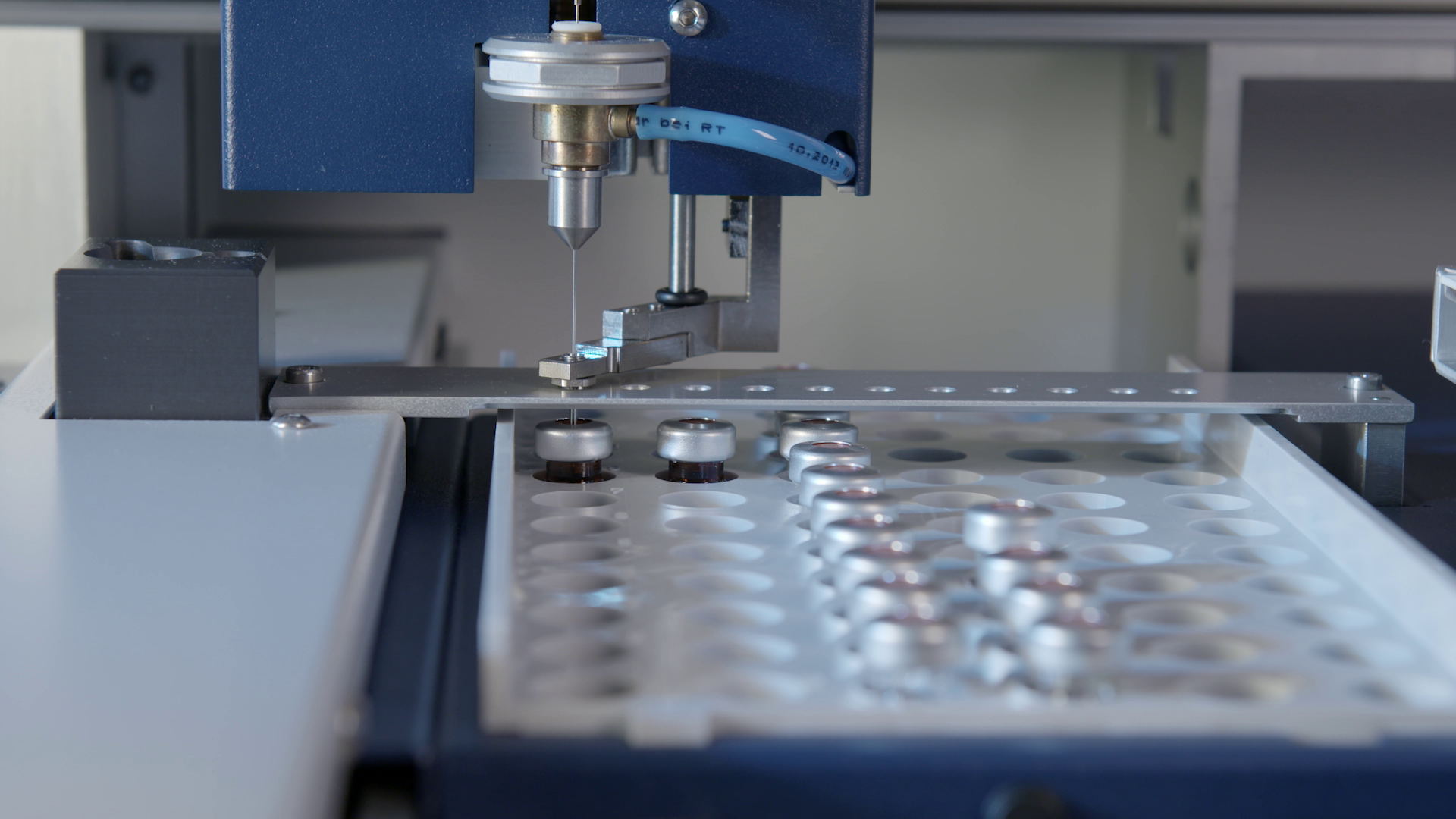

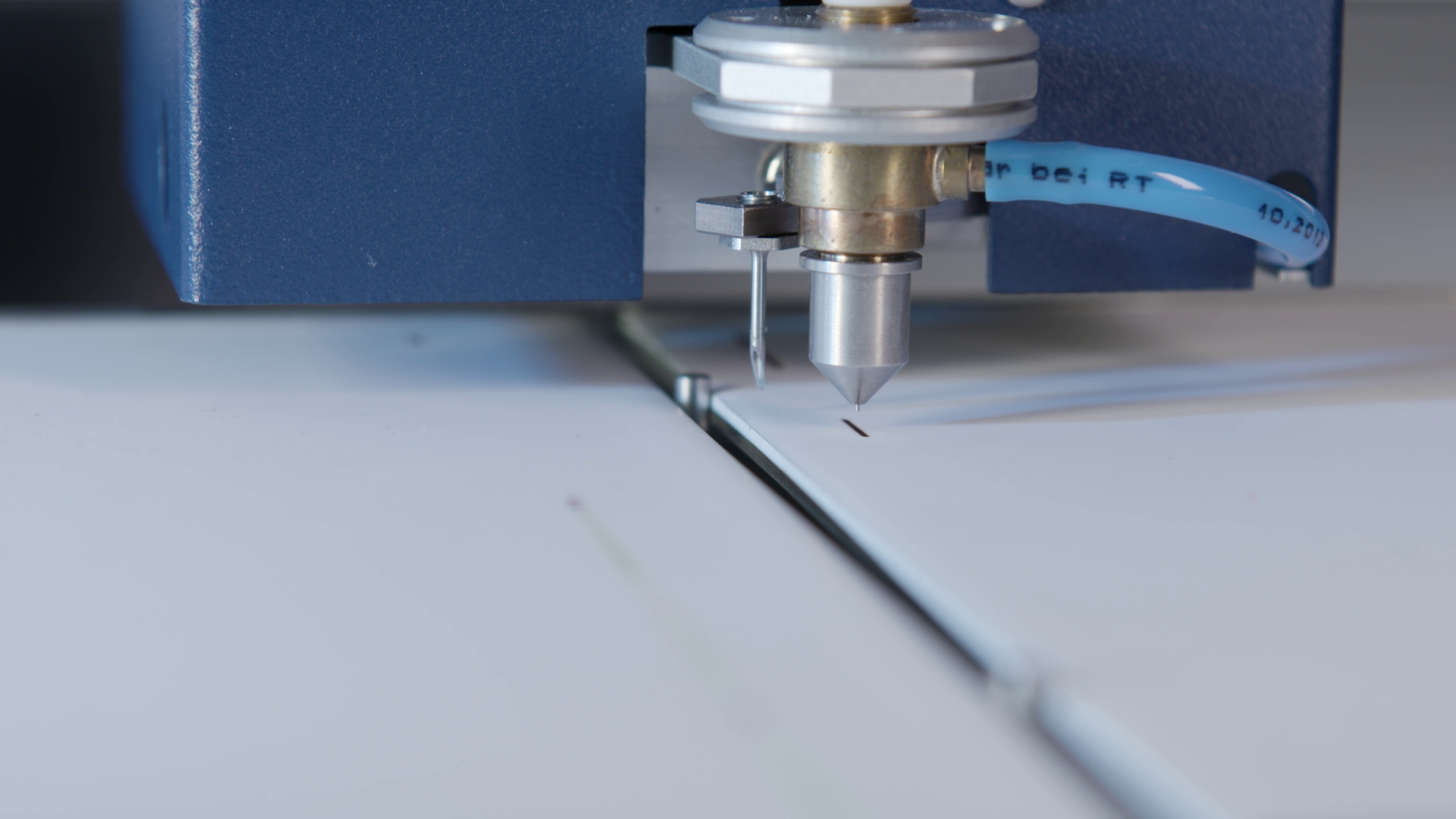

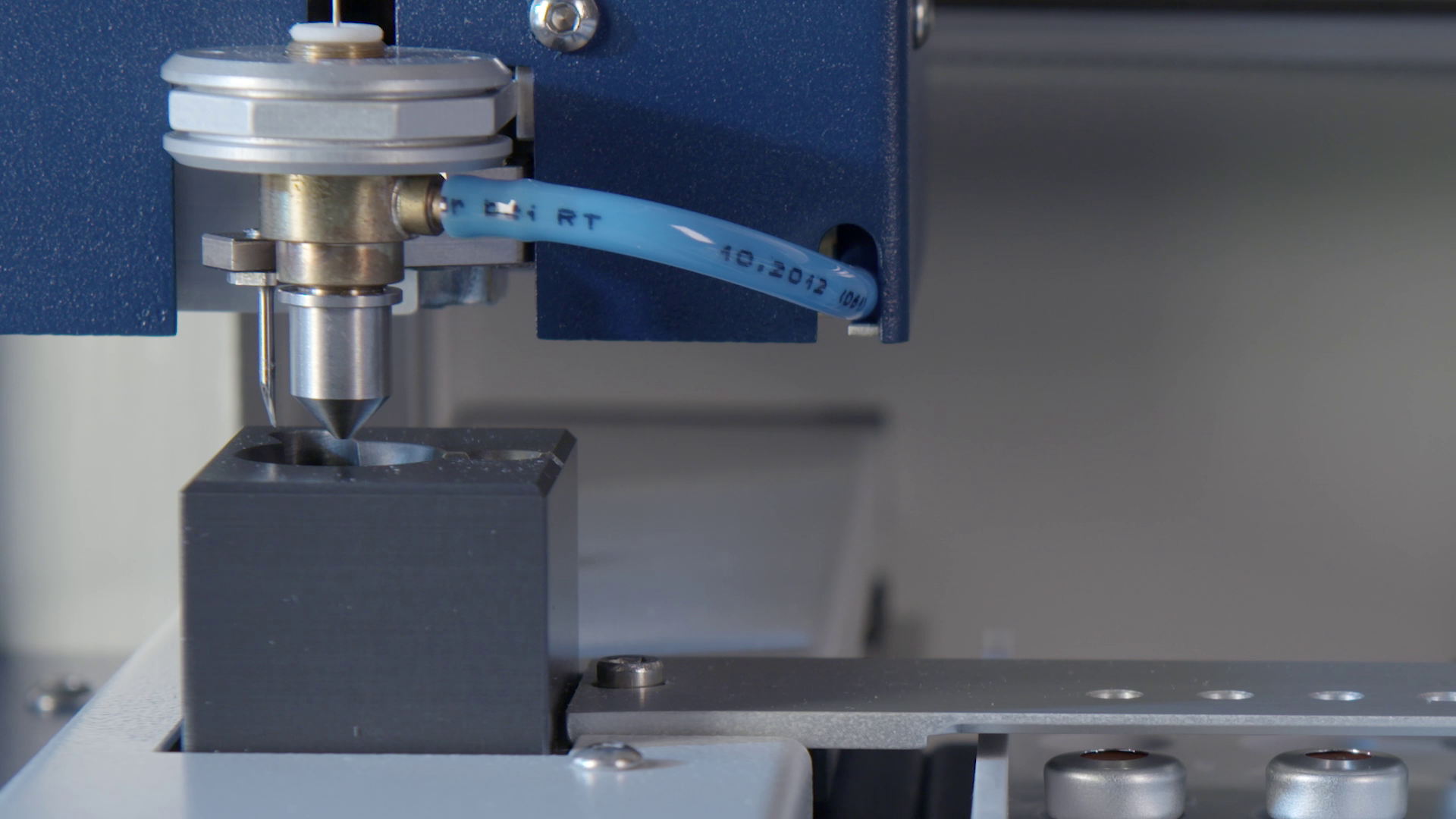

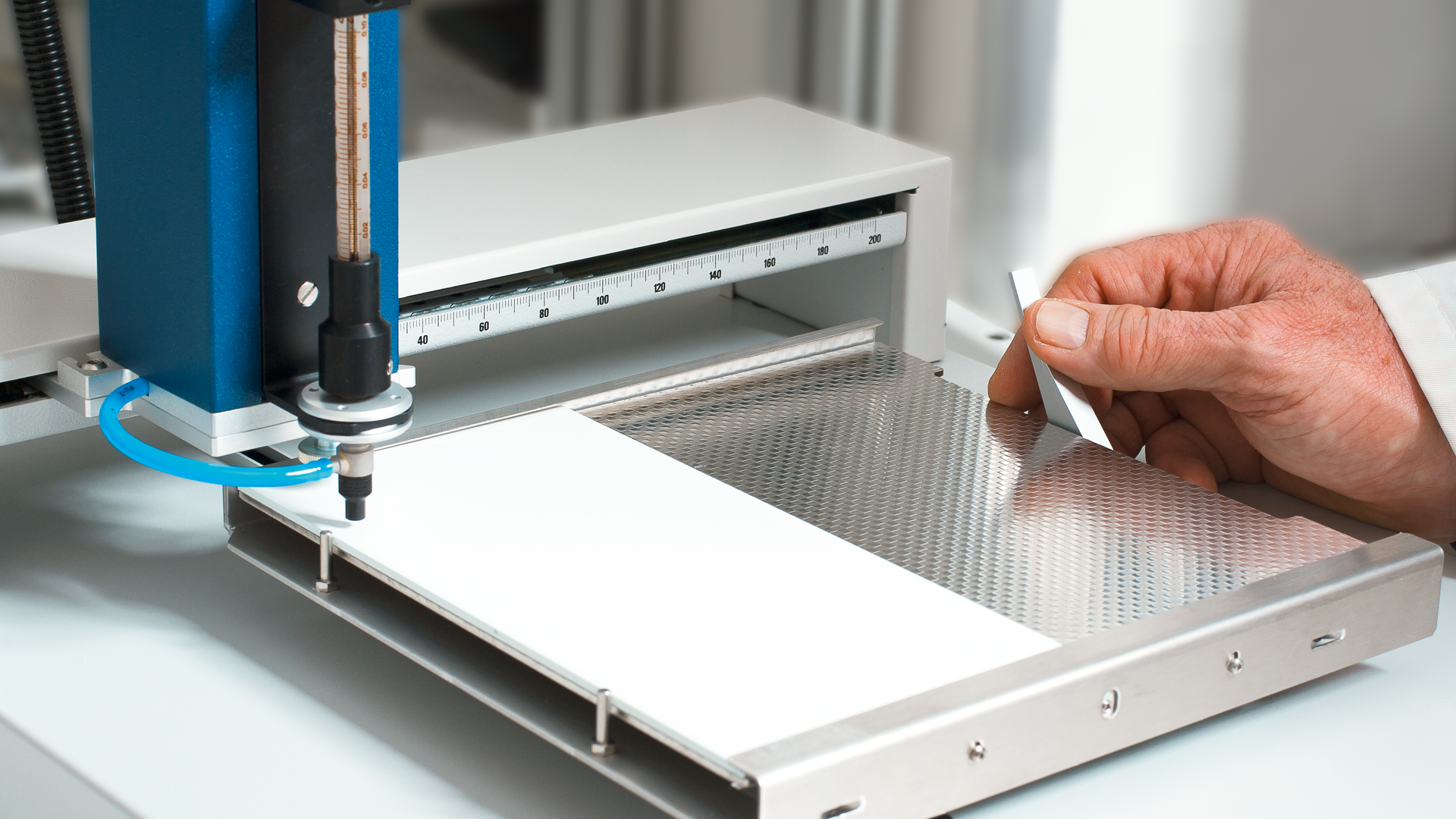

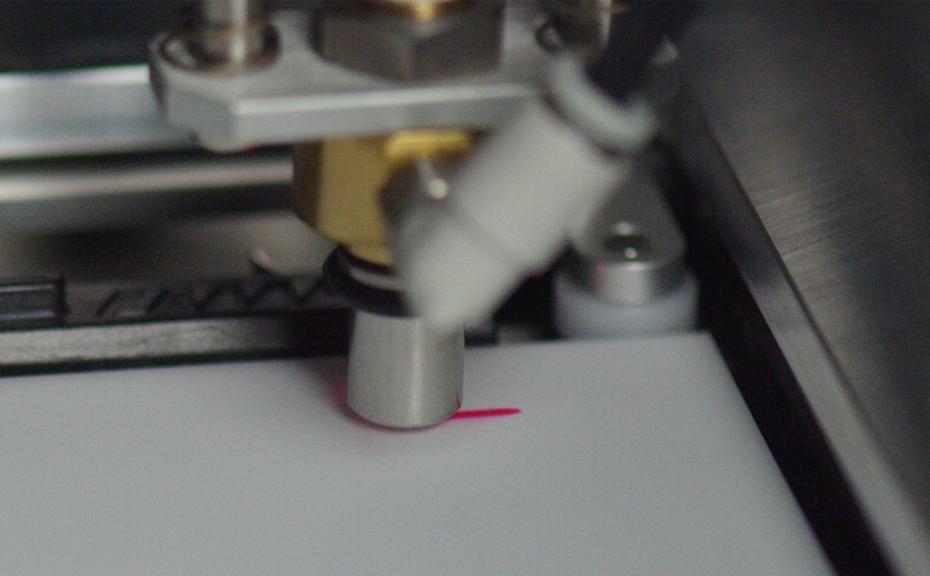

Laser-guided sample application ensures the optimal spraying distance. The needle distance and dosage speed adjust based on the solvent used, guaranteeing precise application of samples as narrow bands.

-

03

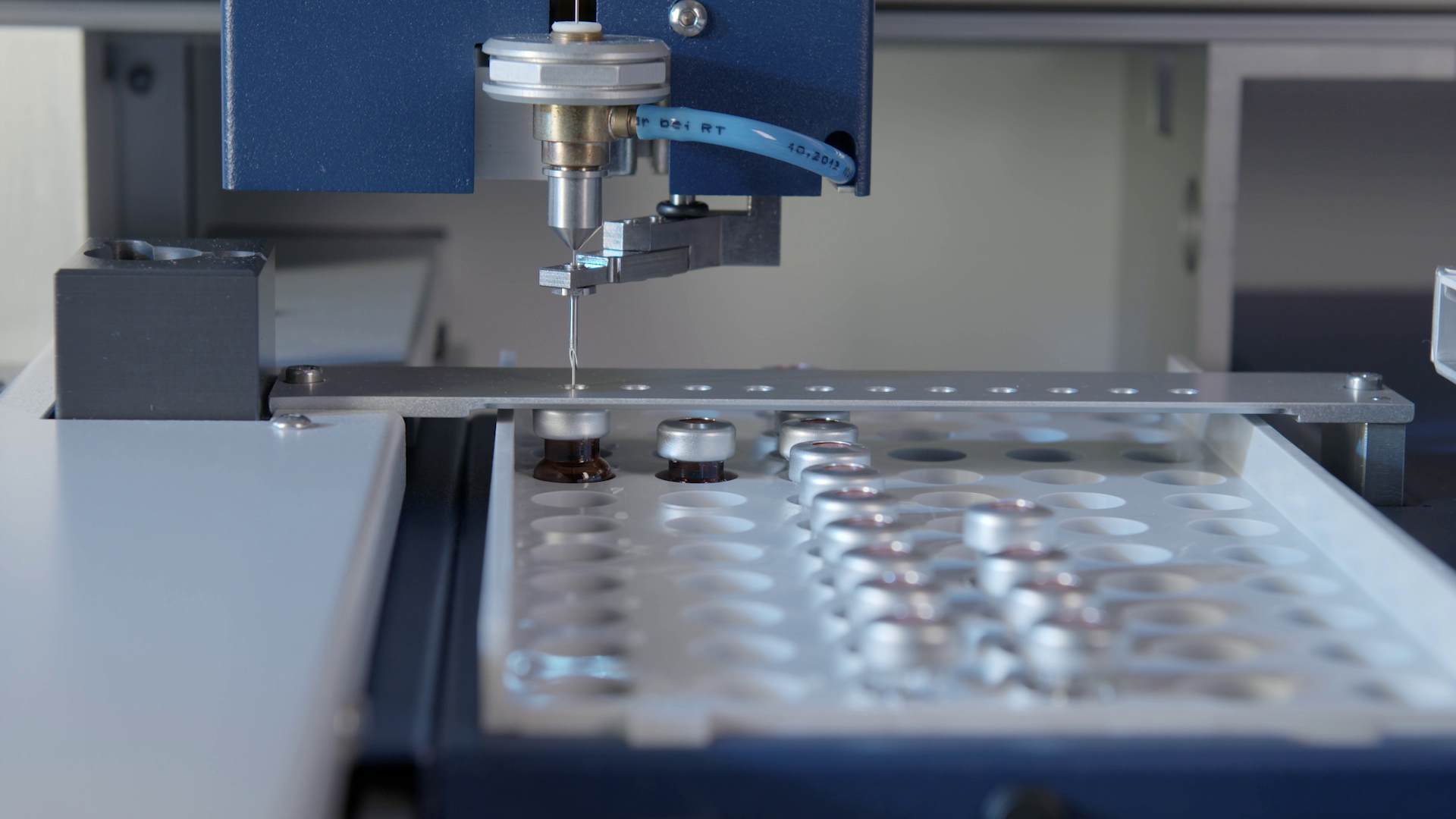

To prevent cross-contamination, the syringe creates an effective separation bubble between the rinsing solvent and the sample solution. The syringe is thoroughly cleaned after each sample application.

-

04

Following sample application, the integrated conveyor transfers the plate from the Module APPLICATION to the Module DEVELOPMENT for further processing.

KEY benefits

-

Highly precise application zones through optimized spraying procedure adapted for each sample solvent

-

Advanced cleaning capacities (two rinsing solutions)

-

Improved cleaning procedure and application strategy to prevent cross contamination

-

Minimized sample and solvent consumption

Technical specifications

-

General data

-

Electrical data

-

Mechanical data