Process Step: All

CAMAG® HPTLC PRO Module DEVELOPMENT

HPTLC PRO

Module DEVELOPMENT

CAMAG® HPTLC PRO

Module DEVELOPMENT

In a nutshell

Full Automation for Reproducible and Efficient development

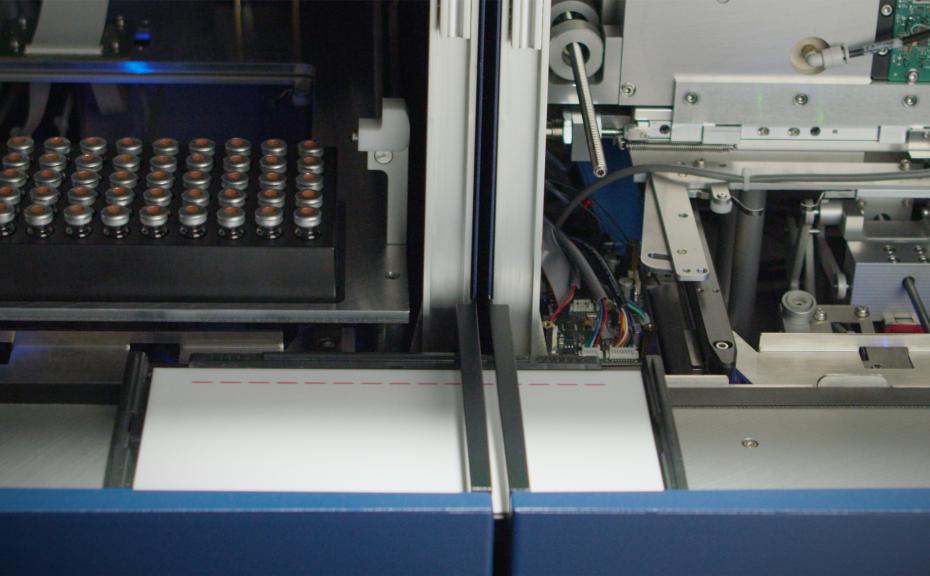

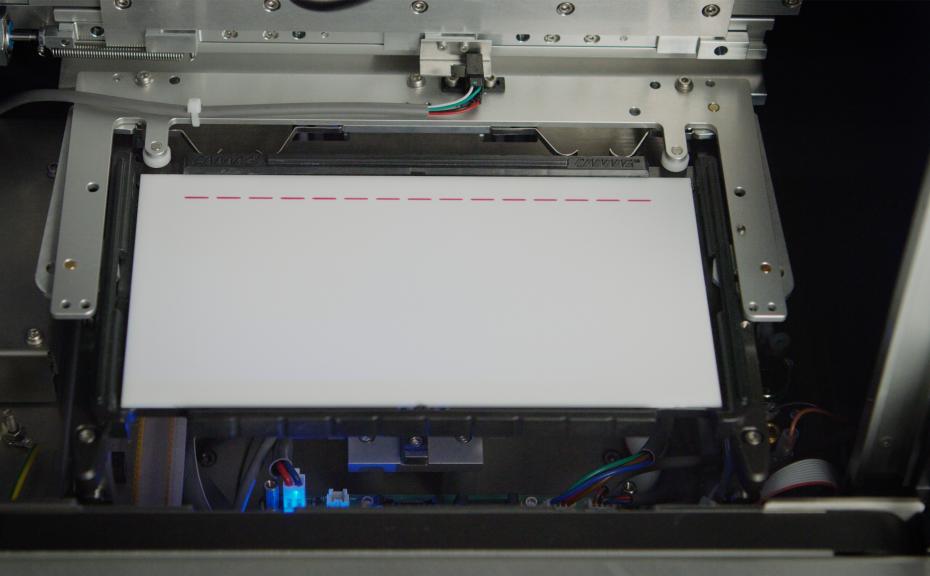

[development-large]The advanced developing chamber of the HPTLC PRO Module DEVELOPMENT revolutionizes chromatography by fully controlling the gas phase, ensuring highly reproducible results, and significantly reducing pre-conditioning and activation time.

-

5

HPTLC glass plates -

3

different developing solvents

Controlled by visionCATS HPTLC Software, the Module DEVELOPMENT autonomously develops up to five HPTLC glass plates (20 × 10 cm) sequentially, using up to three different developing solvents.

-

Part of the fully automated HPTLC PRO SYSTEM

-

Development of up to 5 HPTLC plates (20 x 10 cm)

-

Supports up to 3 different developing solvents

-

HPTLC glass plates (20 x 10 cm)

-

Software-controlled by visionCATS

Stand-alone operation

With HPTLC PRO, users have the choice to either operate a module as stand-alone or together with other modules in a SYSTEM MODE.

SYSTEM MODE

SMOOTH & PRECISE OPERATION

-

01

After application of all samples, the plate is moved to the Module DEVELOPMENT.

-

02

The plate containing the samples applied is ready to be loaded into the developing chamber.

-

03

The tilting mechanism moves the plate from a horizontal to a vertical position into the developing chamber, where it is then developed according to the selected method.

-

04

After development and drying in the chamber, the plate is returned to a horizontal position, ready to be transferred from the Module DEVELOPMENT to other modules for further processing.

KEY benefits

-

Low chamber volume for better control of the gas phase

-

Fast activation and pre-conditioning of the stationary phase (due to active circulation of the gas phase)

-

Full control of the gas phase during development

-

Sensor-controlled constant volume of the developing solvent in the chamber during development

-

Significant time savings due to active gas phase handling

-

Optimized cleaning procedure between different developing solvents

-

User-independent reproducibility

Technical specifications

-

General data

-

Electrical data

-

Mechanical data

CAMAG® AMD 2 System Automated Multiple Development

CAMAG®

AMD 2 System

In a nutshell

high resolution, precision, and repeatability

The separation of complex samples is a challenging task for every chromatographic system, particularly when the sample components span a wide polarity range.

The AMD procedure offers an excellent solution as it allows stepwise gradient elution over increasing separation distances. As a result acids, bases, neutral, hydrophilic, and lipophilic substances can be separated in a single AMD run. This makes AMD suitable for a variety of applications.

The technique is frequently used in lipid analysis and in routine analysis of drinking water. Pigment formulations with a complex composition, resins as well as additives of mineral oil products are other typical applications of AMD analysis.

-

Automated multiple development

-

Stepwise gradient elution over increasing separation distances

-

Enhanced separation capacity

-

HPTLC glass plates (20 x 10 cm), only

-

Software-controlled with visionCATS

THE PRINCIPLE OF

THE AMD PROCEDURE

-

The HPTLC plate is developed repeatedly in the same direction

-

Each successive run extends over a longer solvent migration distance than the one before

-

Between runs, the solvent is completely removed from the developing chamber and the layer is dried under vacuum

-

Each successive run uses a solvent of lower elution strength than that of the one used before. In this way, a stepwise elution gradient is formed

-

The combination of focusing effect and gradient elution results in extremely narrow bands. Their typical peak width is about 1mm. This means that, with the available separation distance of 80mm, up to 40 components can be completely resolved, i.e with base line separation

-

With visionCATS the AMD 2 can be IQ/OQ qualified and used in a cGMP environment. Operated with the mentioned software, the AMD 2 supports compliance with 21 CFR Part 11.

The AMD 2, like other software-controlled CAMAG instruments, communicates with visionCATS. The gradient, made from up to 5 solvent bottles, is defined by input into a table in visionCATS. Gradient and solvent migration distance for each run can be shown graphically for verification. Then all individual runs of the developing program are performed fully automatic and monitored by visionCATS.

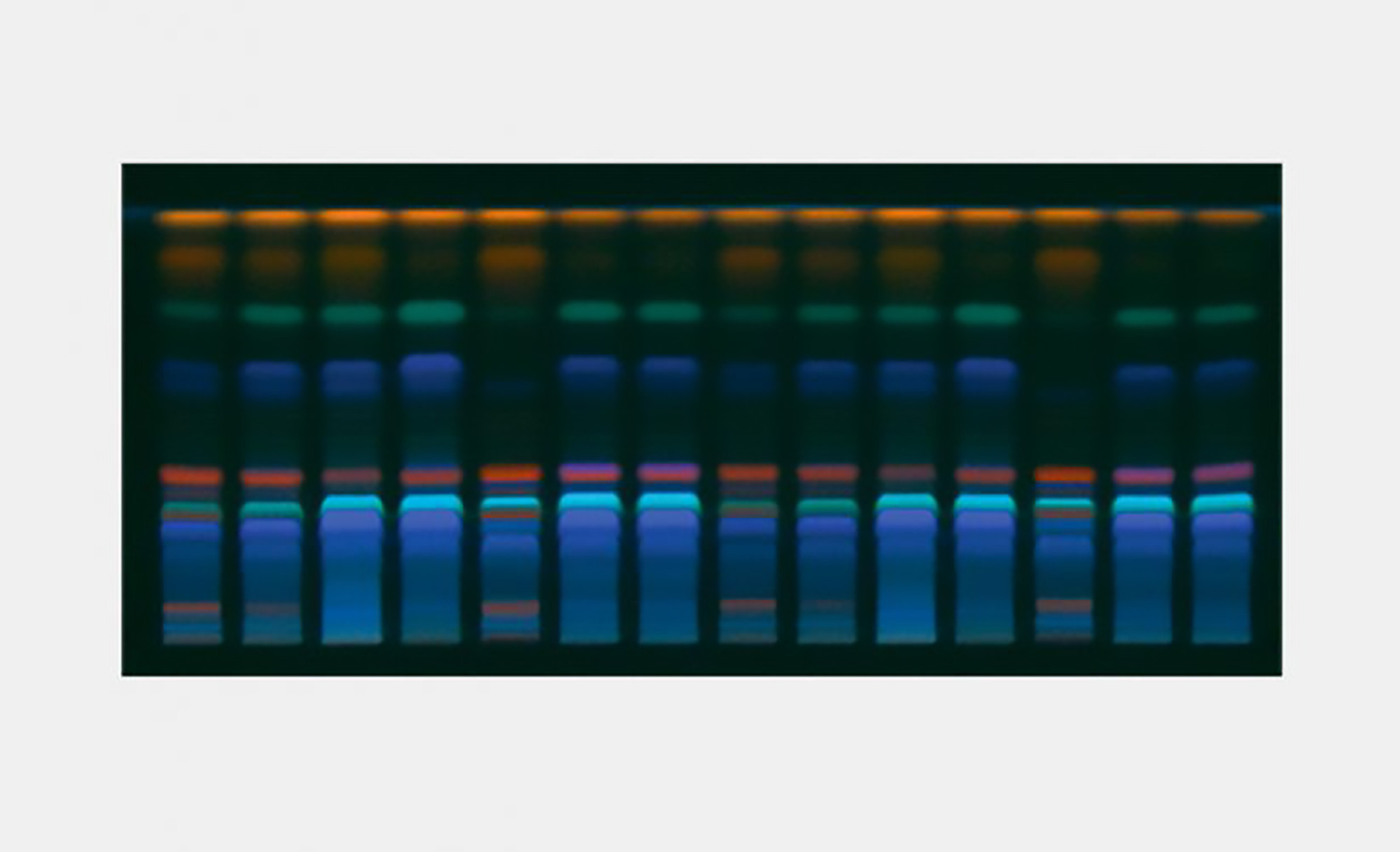

SEPARATION OF VARIOUS

RHUBARB SAMPLES BY AMD 2

HPTLC chromatogram of rhubarb under UV 366 nm, derivatized with Natural Product reagent; AMD gradient in 10 steps: methanol – dichloromethane (40:60) to (10:90) in 9 steps, 40 mm solvent migration distance, then one isocratic step methanol – dichloromethane (10:90) over 70 mm solvent migration distance

Technical specifications

General data

CAMAG® Automatic Developing Chamber 2 (ADC 2)

CAMAG®

Automatic Developing Chamber 2

In a nutshell

the standard for reproducible results

Development is a critical step in HPTLC, and the ADC 2 ensures reproducible results by fully automating the development process and eliminating environmental influences. The ADC 2 precisely controls layer activity, chamber saturation, developing distance, and final drying, ensuring consistent chromatographic separations.

This advanced system offers two operational modes: standalone with parameter input via a keypad or software-controlled operation using visionCATS. The software mode provides enhanced process monitoring, parameter documentation, and detailed reporting, making the ADC 2 suitable for regulated environments.

Designed for compatibility with 20 x 10 cm Twin Trough Chambers, the ADC 2 maintains the conditions of established analytical procedures while minimizing operational variability. The optional Humidity Control feature enables chromatography at defined layer activity, critical for method development and studying the effects of relative humidity. Integration with visionCATS software supports compliance with cGMP/GLP requirements and 21 CFR Part 11, ensuring its suitability for highly regulated workflows.

-

Fully automated development

-

Development in 20 x 10 cm Twin Trough Chamber

-

HPTLC plates (20 x 10 cm)

-

Operation in stand-alone mode or software-controlled

-

Fully traceable operation

-

Option “Humidity Control” allows reproducible chromatography

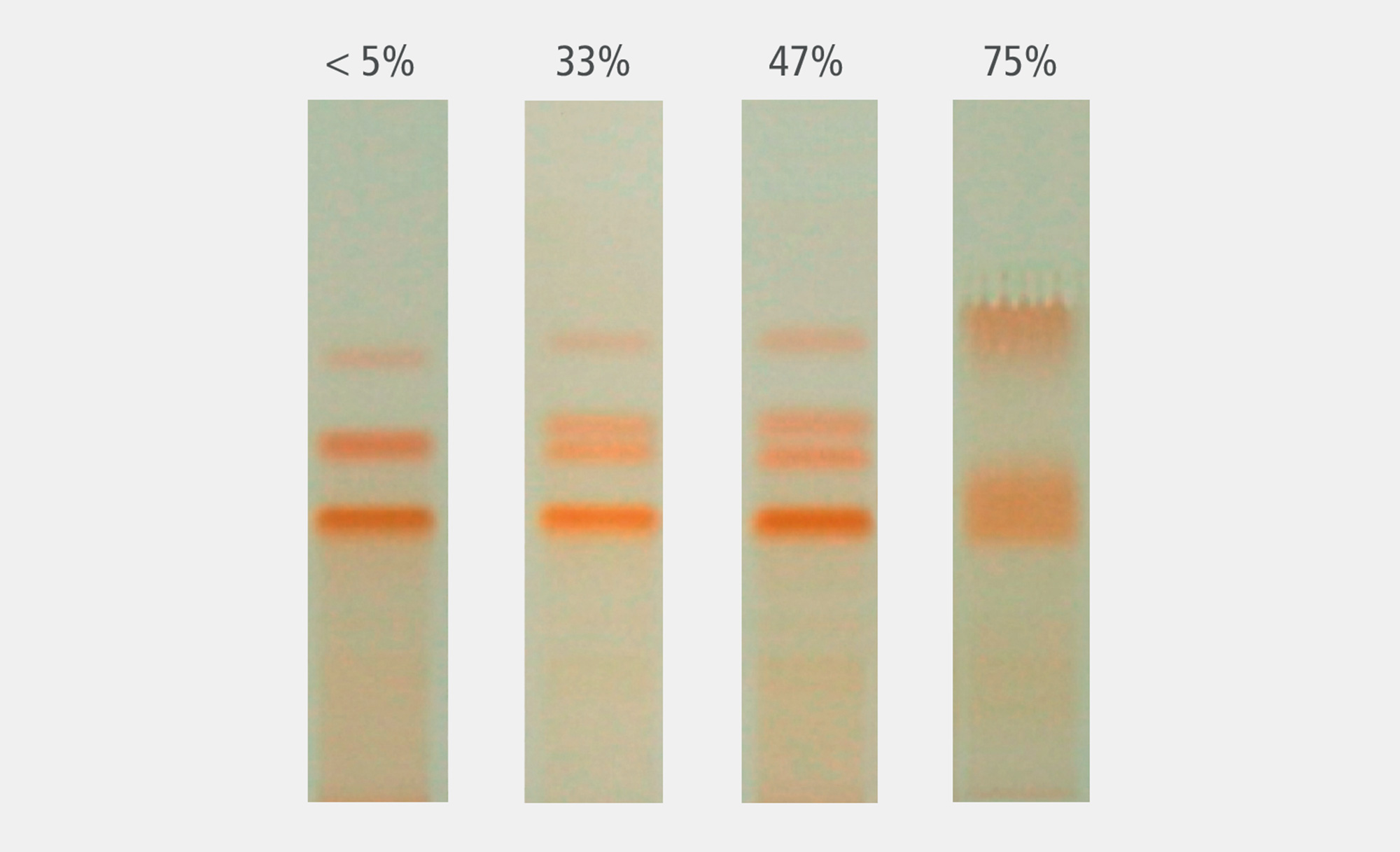

Example: ADC 2 SEPARATION OF POLYPHENOLS IN GREEN TEA

EFFECTS OF RELATIVE HUMIDITY

Developing solvent: toluene, acetone, formic acid 9:9:2 (v/v/v)

Derivatization: Fast Blue Salt B

Technical specifications

General data

CAMAG® Twin Trough Chamber

Twin Trough Chamber

In a nutshell

Consistent Results, Minimal Solvent Use

This is a classical developing tank for Thin-Layer Chromatography. Compared to a Flat Bottom Chamber less solvent is needed. A Twin Trough Chamber reduces disposal problems and allows preconditioning of the plate with any solvent and for any duration. For preconditioning or saturation the trough opposite to the plate is filled with developing solvent. The use of a saturation pad is recommended for a fast, homogeneous and reproducible chamber saturation process.

-

Glass tank with two troughs for manual development

-

Available for 20 x 10 cm, 20 x 20 cm, and 10 x 10 cm plates

-

Steel or glass lid

CAMAG® Flat Bottom Chamber

Flat Bottom Chamber

In a nutshell

NEW STANDARD OF REPRODUCIBILITY

This is a classical developing tank for Thin-Layer Chromatography. Compared to a Twin-Trough-Chamber more solvent is needed. Also a Twin-Trough-Chamber reduces disposal problems and allows preconditioning of the plate with any solvent and for any duration.

-

Glass tank with flat bottom for manual development

-

Available in the formats 20 x 20 cm and 10 x 10 cm

-

Steel or glass lid

CAMAG® Horizontal Developing Chamber

CAMAG®

Horizontal Developing Chamber

Efficient Chromatography

In the Horizontal Developing Chambers, HPTLC plates can be developed from both opposing sides towards the middle. This permits the number of samples to be doubled as compared with development in a tank, provided the separation distance of 45 mm, i.e. 50 mm minus 5 mm distance from the edge, is sufficient. This chamber type is often used for screening purposes. The obtained chromatograms differ from those obtained with the same mobile phase system developed in vertical chambers.

-

Chamber for horizontal development

-

Available in the formats 20 x 10 cm and 10 x 10 cm

-

Development from both plate sides possible to double the number of samples

-

Development in sandwich or tank configuration

-

Low solvent consumption

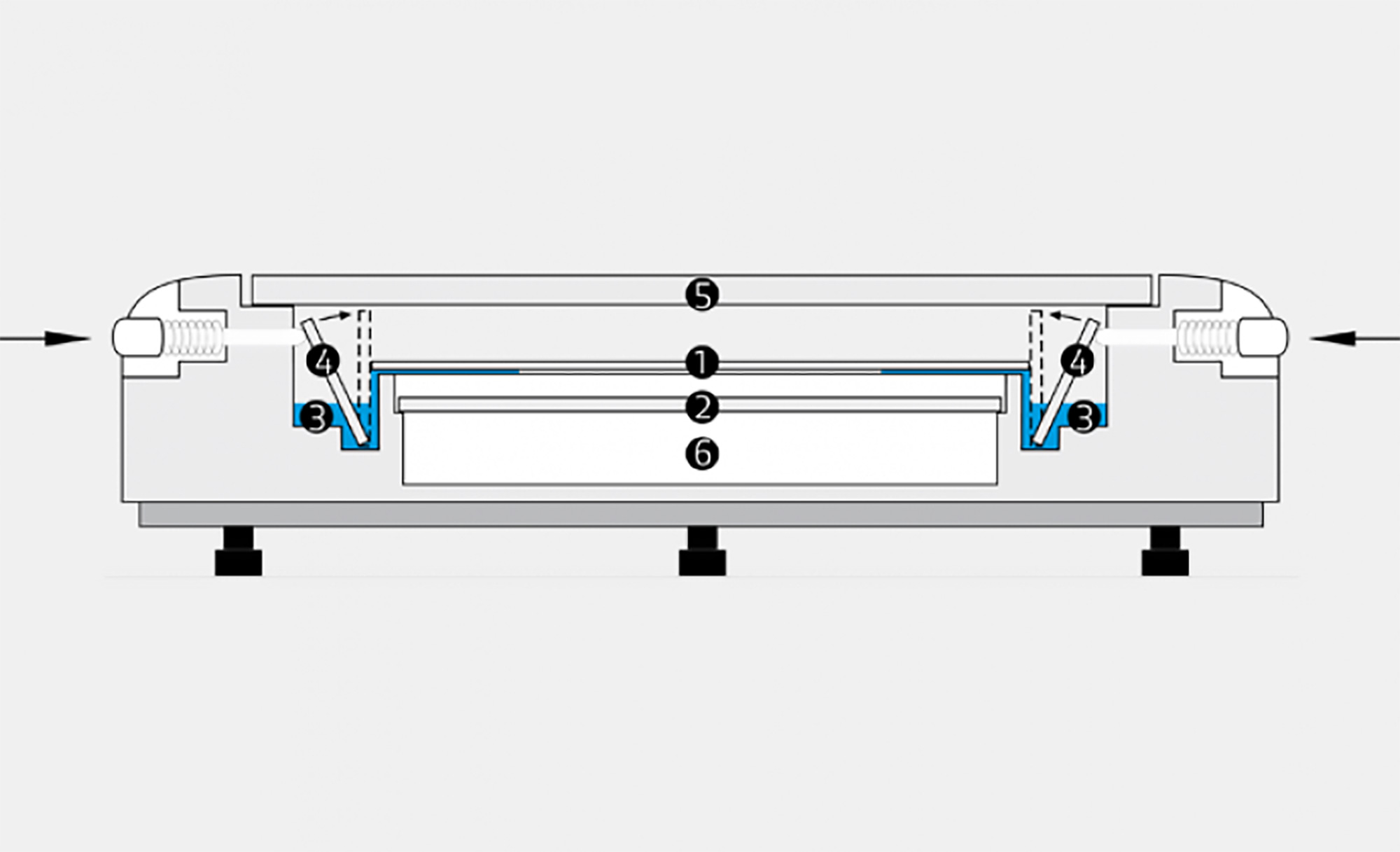

CHAMBER SCHEME

-

HPTLC plate (layer facing down)

-

Glass plate for sandwich configuration

-

Reservoir for developing solvent

-

Glass strip

-

Cover plate

-

Conditioning tray

Horizontal Developing Chamber scheme

CAMAG® smartAlert

CAMAG®

smartAlert

Smart Development Monitoring

The CAMAG® smartALERT is an innovative device designed to enhance the precision and reliability of chromatographic development processes. It monitors the solvent front during the development of TLC/HPTLC plates and alerts users with visual and audible signals when the front reaches the defined position.

This ensures accurate timing, prevents overdevelopment, and improves reproducibility in analyses. Compatible with glass chambers and plates in 20 x 20 cm, 20 x 10 cm, and 10 x 10 cm formats, the smartALERT is user-friendly, featuring simple one-button operation and multiple alarm tones. Battery-powered for convenience, it is an essential tool for optimizing laboratory workflows and maintaining high-quality chromatographic results.

-

Stops at set distance

-

Visual and audible alerts

-

Easy to operate

-

Compatible with standard chamber and plate formats

-

Four different alarm sounds

-

Runs on batteries

CAMAG® HPTLC Vario System

CAMAG®

HPTLC Vario System

In a nutshell

Optimization of developing conditions

The CAMAG® HPTLC Vario System is designed to optimize chromatographic conditions efficiently by allowing simultaneous testing with up to six different solvent systems. It enables side-by-side simulation of both sandwich and tank configurations, facilitating direct comparison of results. Additionally, the system allows testing of six distinct preconditioning or activation conditions of the silica gel, adjusting to various relative humidities. This versatility accelerates method development and enhances the precision of separation conditions, making it an invaluable tool for laboratories aiming to streamline their chromatographic processes.

-

Development with six different developing solvents can be tested side by side

-

Sandwich as well as tank configuration can be simulated

-

Six different conditions of precondition can be tested simultaneously

-

Effect of six different relative humidities can be tested simultaneously

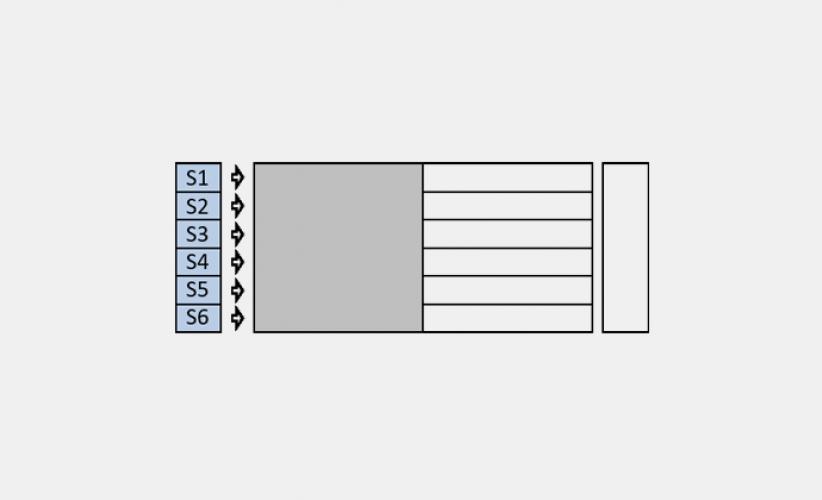

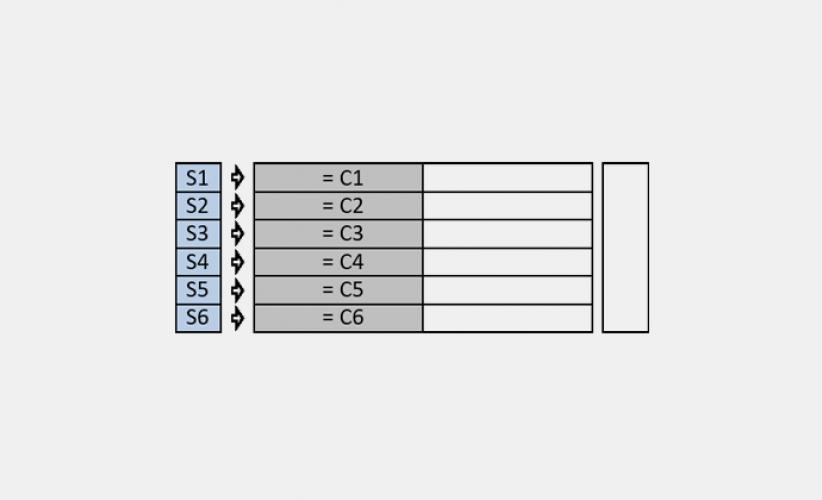

TIME SAVING METHOD DEVELOPMENT AND OPTIMIZATION

SEPARATION CONDITIONS USING THE HPTLC VARIO SYSTEM

Examples of application

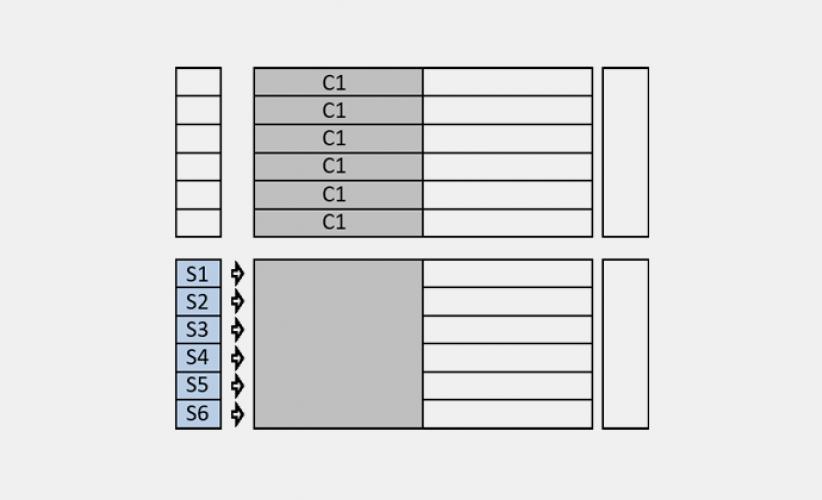

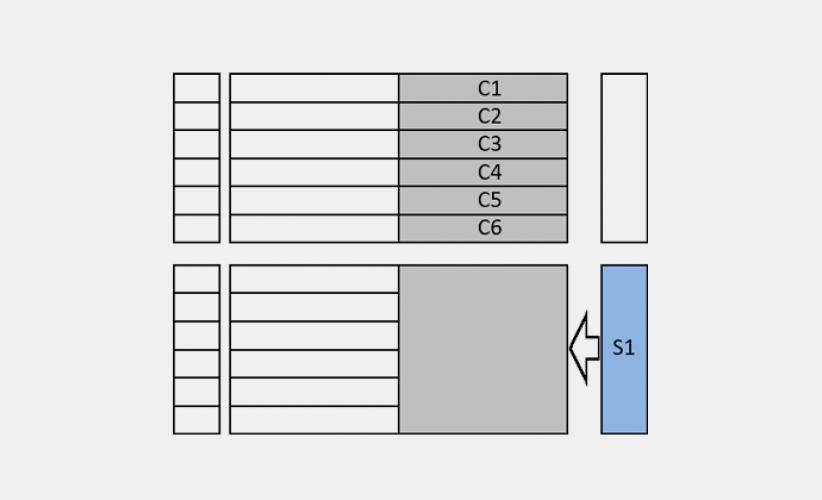

Schematic:

-

S1-S6

developing solvents

-

C1-C6

solvents for precondition or activation of the silica gel at different related humidities

OPTIMIZATION OF THE DEVELOPING SOLVENT WITHOUT PRECONDITIONING

Development with six different developing solvents (S1-S6) side by side, without preconditioning.

OPTIMIZATION OF THE DEVELOPING SOLVENT WITH PRECONDITIONING

Development with six different developing solvents (S1-S6) side by side and with the condition troughs containing the same six solvents (C1-C6).

OPTIMIZATION OF THE DEVELOPING SOLVENT AFTER UNIFORM LAYER PRECONDITIONING

Preconditioning or activation to a certain relative humidity of all tracks with the same solvent (C1) and development with six different developing solvents (S1-S6).