CAMAG®

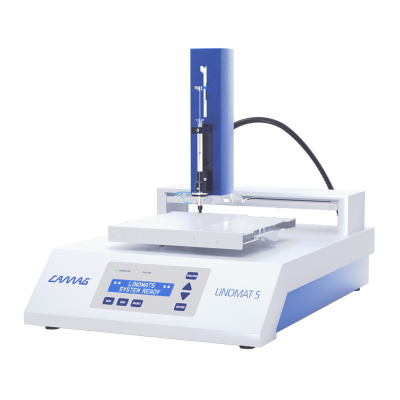

AUTOMATIC TLC SAMPLER 4

In a nutshell

The key to quality and reproducibility

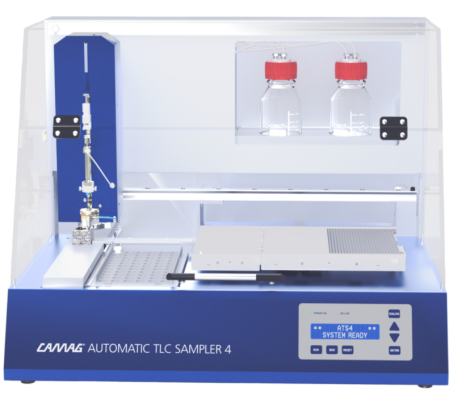

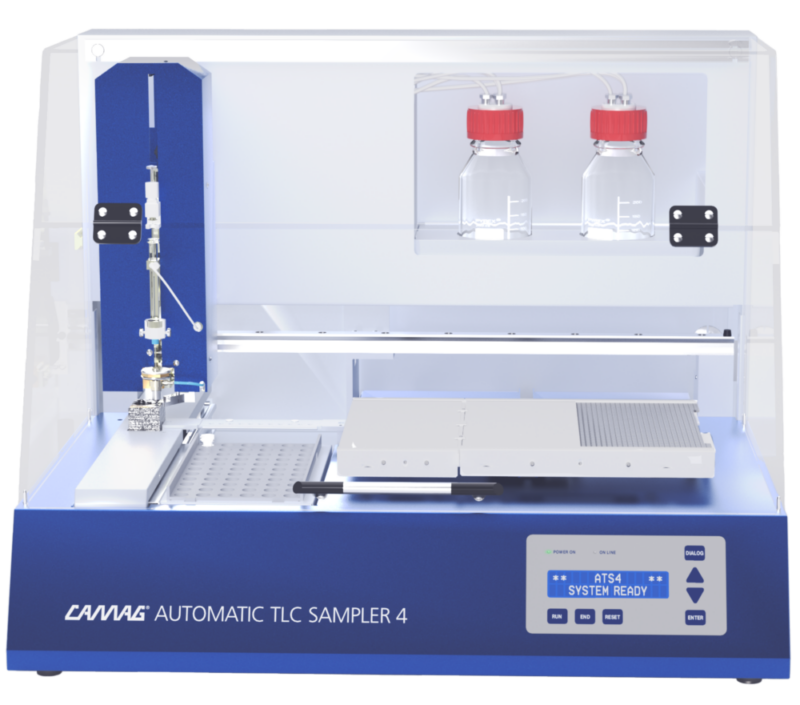

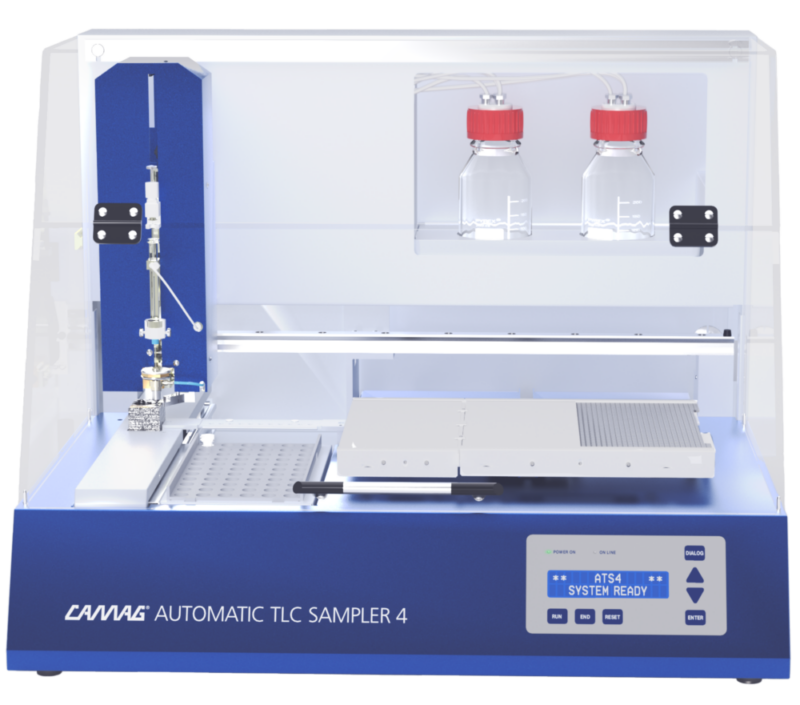

The Automatic TLC Sampler 4 initiates the HPTLC process by applying samples, which plays a crucial role in determining analysis quality. Additionally, automation enhances productivity, making the HPTLC lab more efficient. Designed for routine operations and high throughput, the ATS 4 efficiently handles both qualitative and quantitative analyses, as well as preparative separations.

Specifically, the Automatic TLC Sampler 4 applies samples as bands, spots, or rectangles using the spray-on technique. It precisely delivers large volumes and concentrates rectangles into narrow bands with a high-strength elution solvent before chromatography.

Furthermore, the ATS 4 supports “overspotting,” sequentially applying samples onto the same position. This feature proves particularly useful for pre-chromatographic derivatization, spiking, and other similar procedures, enhancing its versatility for a range of applications.

-

Fully automated sample application

-

Application of bands, spots or rectangles

-

Any plate format up to 20 x 20 cm (glass or aluminium foil)

-

Spray-on application or by contact transfer

-

Software-controlled by visionCATS

OPERATION WITH VISIONCATS Software

The instrument parameters dialog box provides user-friendly default settings. For example, selecting a solvent similar to the one in use allows the software to automatically adjust instrument settings based on viscosity, volatility, and surface tension. Additionally, the filling/rinsing process, which controls syringe rinsing frequency and filling repetition, can be customized for specific tasks.

How the ATS 4 works

01

An application sequence begins with sample uptake. The vial septum is punctured, and the needle is inserted into the sample vial through the puncture. The syringe is then filled with the sample solution.

02

The septum punch retracts, ensuring that the tightly sealed septum wipes off the exterior of the needle.

03

Before the first application from a newly filled syringe, a small sample volume is pre-dosed onto a waste plate to ensure consistent conditions at the needle tip. This pre-dosage is performed in the same manner as sample application, either through contact spotting or the spray-on technique.

04

The syringe moves to the programmed position of the plate and starts application of the desired sample volume. If several applications of the same sample have been programmed, these are applied in sequence from the same syringe filling, provided the remaining volume is sufficient. Otherwise, the syringe is automatically refilled.

05

After the final sample application, the syringe is emptied into the waste bottle.

06

The syringe is filled with rinsing solvent, and the plunger moves beyond the side connection to remove any excess solvent. Once the rinsing solvent is emptied into the waste bottle, the dosing system is prepared for the next application sequence.

Watch the ATS 4 in action

Technical specifications

-

Object supportFor objects up to 20 x 20 cm

-

Stage driveX-drive (turret) Stepper motor 1600 steps/rev. 4 steps = 0.1 mm Maximum speed 200 mm/s with acceleration ramp Positions programmable: 5.0 – 195.0 mm in 0.1 mm steps Y-drive (stage) Step motor 3200 steps/rev. 8 steps = 0.1 mm Maximum speed 200 mm/s with acceleration ramp Positions programmable: 5.0 – 195.0 mm in 0.1 mm steps

-

Dosage syringe driveStepping motor 1600 steps/rotation 100 nL = 120 steps with 100 µL syringe or 24 steps with 500 µL syringe

-

Sample dosage syringeselectable 100 µL or 500 µL

-

Memory10 methods, backup min. 10 years

-

LCD display2 lines of 16 characters ea.

-

Power connection85–250 V~ 47–63 Hz 30 VA

-

Gas supply4–6 bar (60–90 PSI) preferably nitrogen; consumption approx. 1.0 L/min

-

Dimensions (W x D x H)360 x 510 x 410 mm

-

Weight12.5 kg

What you need to get started

Ordering Information

-

022.7400

CAMAG® Automatic TLC Sampler 4 (ATS 4)

for fully automatic application of samples as spots, bands or rectangles including overspotting in qualitative and quantitative TLC analysis. Complete with instrument cover, sample rack for 66 standard 2 mL vials, 90–230 V Including Dosing Syringe Starter Kit, containing: 25 µL Dosing syringe (695.0053), Spray-on needle for dosing syringe (695.0046), Contact transfer needle for dosing syringe (695.0047)

-

022.7410

CAMAG® Automatic TLC Sampler 4 (ATS 4)

with heated spray nozzle for fully automatic application of samples as spots, bands or rectangles including overspotting in qualitative and quantitative TLC analysis. Complete with instrument cover, sample rack for 66 standard 2 mL vials, 90–230 V Including Dosing Syringe Starter Kit, containing: 25 µL Dosing syringe (695.0053), Spray-on needle for dosing syringe (695.0046), Contact transfer needle for dosing syringe (695.0047)

-

028.0000

CAMAG® HPTLC Software visionCATS: Basic Version

including access and control of all instruments – 1 server, 1 client Instrument Diagnostics (xQ), analytical reports – access to method library. Needs to be purchased separately and is not included in any Ultimate Package.

-

022.7450

Dosing Syringe Starter Kit, containing: 25 µL Dosing syringe (695.0053), Spray-on needle for dosing syringe (695.0046), Contact transfer needle for dosing syringe (695.0047)

Interested in the product?

Reach out to your local distributor and enjoy faster, improved results at reduced costs.