Process steps

HPTLC is a highly flexible technique. The plate moves through process steps with adjustable parameters, and the level of automation increases with the demand for precise results

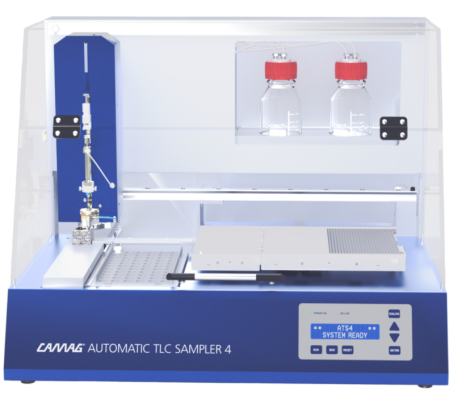

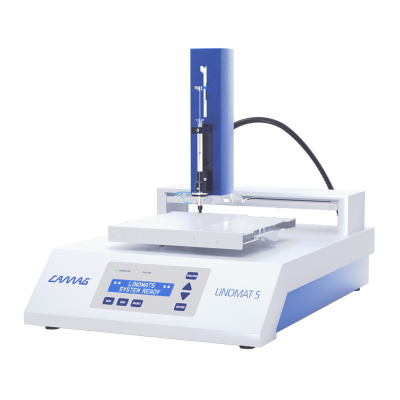

APPLICATION

Application of bands by spray-on technique, using the CAMAG® HPTLC PRO Module APPLICATION, the CAMAG® Automatic TLC Sampler 4 (ATS 4), or the CAMAG® Linomat 5 allows the optimal application of samples. Starting zones in the form of narrow bands ensure the best resolution. The high-end instruments are equipped with a spraying nozzle to further optimize the spraying effect depending on the sample solvent used.

Matching products

DEVELOPMENT

Development is the key step in HPTLC to accurately separate the substances in a sample. The selected chamber and chamber configuration play an important role with regard to the separation and the ability to reproduce the chromatography. In addition to stationary and mobile phase, HPTLC features a gas phase, which can significantly influence the result of the separation. A development can occur in an unsaturated, partially saturated, saturated and/or preconditioned chamber.

The primary focus of an automatic chamber (CAMAG® HPTLC PRO Module DEVELOPMENT, CAMAG® Automatic Developing Chamber 2 (ADC 2) or CAMAG® AMD 2 System Automated Multiple Development) is to make the development more reproducible and independent of human interaction. With an automatic chamber, the activity of the stationary phase can be adjusted. The layer is automatically brought in contact with the mobile phase and the migration is monitored. After completion of chromatography, the plate is dried.

Matching products

DERIVATIZATION

It is an inherent advantage of HPTLC that all analytes remain stored on the plate and can be readily derivatized after chromatography. Analytes that do not respond to visible or UV light can be rendered detectable. In many cases, analytes or classes of analytes can be identified by specific reagents, enabling their selective detection.

Pre-chromatographic derivatization is also possible by overspraying the sample application zones with the CAMAG® Linomat 5, the CAMAG® Automatic TLC Sampler 4 (ATS 4) or CAMAG® HPTLC PRO Module APPLICATION.

In most cases, the derivatization reaction needs to be completed by heat treatment. Heating the plate at the desired temperature with a plate heater (CAMAG® TLC Plate Heater 3) specifically designed for this purpose is highly recommended. A plate heating unit is an integral part of the CAMAG® HPTLC PRO Module DERIVATIZATION.

Matching products

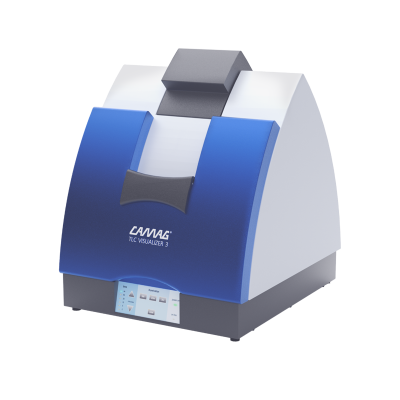

DETECTION

In contrast to other chromatographic techniques, HPTLC offers the unique opportunity to “visualize” the chromatographic result directly for the human eye.

Colored substances can be seen directly on the plate; others are conveniently changed into colored derivatives. Compounds that absorb UV light of UV 254 nm are visualized with the help of a fluorescence indicator (F254) impregnated plate appearing as gray to black zones on this plate, whereas the rest of the plate remains fluorescent.

Substances excited to fluoresce by UV 366 nm either with or without derivatization can also be visualized. For electronic image acquisition a digital camera captures visible polychromatic light. The obtained data can be edited, archived and evaluated.

Matching products

MS-INTERFACE

Matching products

PLATE STORAGE

Module to automatically feed HPTLC plates to and store them within the HPTLC PRO SYSTEM.

Hosting two stackers for five clean and five processed HPTLC glass plates (20 × 10 cm), each, the HPTLC PRO Module PLATE STORAGE enables the autonomous operation of the HPTLC PRO SYSTEM. It is essential for sequential development of several plates (Module APPLICATION holds up to 75 samples) by providing the HPTLC PRO SYSTEM with clean plates and storing the processed plates during or after analysis.